Maintenance-free

Pressure stability

Deformation in the rubber leads to higher wear and quickly impacts pressure stability = holding pressure in the chambers; reflux occurs in the stator.

Operating temperature

Friction causes heat and this has a negative impact on the rubber of the stator.

It is therefore important to reduce the heat in the stator by using a suitable rubber compound and through fast heat dissipation.

Irregular rubber thicknesses prevent fast heat transmission.

Pre-stress and pump's operating range

Maintenance-free stator "Ready-to-go" – pre-stressed for immediate use.

3 reasons in favour of the PFT C 4-2 soft system

- 1. process larger grain sizes effortlessly

The decisive argument in favour of the PFT C 4-2 soft system is the release of the stator for grain sizes up to 4 mm (compared to 3 mm for the standard C 4-2).

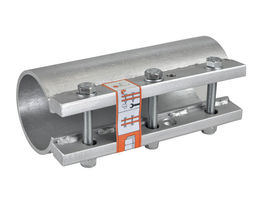

This enables the processing of coarse-grained exterior and interior plasters with a PFT SWING M conveyingpump - ideal for a wide range of applications! - 2. enjoy a maintenance-free system

The PFT C 4-2 soft system is maintenance-free, which makes life much easier for the user. While similar grain sizes can normally only be processed with a clampable system, our system offers a maintenance-free solution that saves time and effort. - 3. reduce the drive power required

Thanks to the reduced preload of the system, less drive power is required. This expands the application possibilities of a PFT SWING M and ensures more efficient and energy-saving utilisation.

Experience the benefits of the PFT C 4-2 soft system and maximise your productivity when processing plaster materials!