Conveying output, max.:

85 l/min

Conveying distance up to:

30 m in DN25

50 m in DN35

Connection value:

400 V, 3 Ph, 50 Hz, 5.5 kW

Control voltage: 42 V

Drive:

Pump motor: 5.5 kW, 400 rpm

2-stage gear box with inclination switch

Star wheel drive: 0.75 kW, 28 rpm

Mixing tube:

Rubber mixing tube with adaptable flange

Mixing shaft:

BIONIK G 4 Machine-applied plaster

Grout outlet with mortar pressure gauge:

DN35 female part

Wheels:

2 castors, 2 double-stop castors

Water connection:

Geka DN19 (3/4") – 2.5 bar working pressure

Operation and control:

Start/stop incl. Water pump control unit

Filling height:

910 mm

Hopper volume:

145 litres ~ 5 sacks (at 30 kg)

Length/Width/Height:

1,200/720/1,530 mm

Total weight:

308 kg

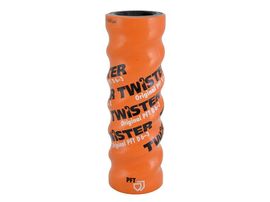

Pump unit:

TWISTER D 6–3 · 20 l/min · 30 bar

Mortar hose:

RONDO DN25 – 15 m

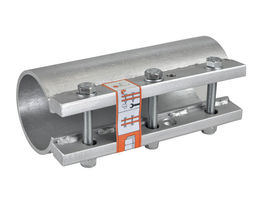

Adapter coupling:

DN35 male part | DN25 male part

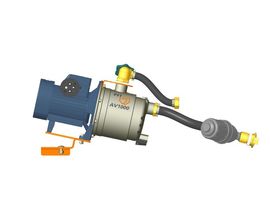

Water pump for pressure boosting:

AV 1000

400 V, 3 Ph, 50 Hz, 0.6 kW

Water flow meter:

150 – 1,500 l/h

Air compressor:

COMP M-250-V5 handy, 400 V,

3 Ph, 50 Hz, 0.9 kW, 250 l/min -

max. 4 bar with pressure switch-off

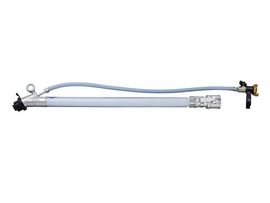

Spraying gun/fine plastering device:

DN25-360° S14 200 Geka

Connection cable:

Not included

Water hose/air hose:

DN12 (1/2") Ewo | Geka – 16 m